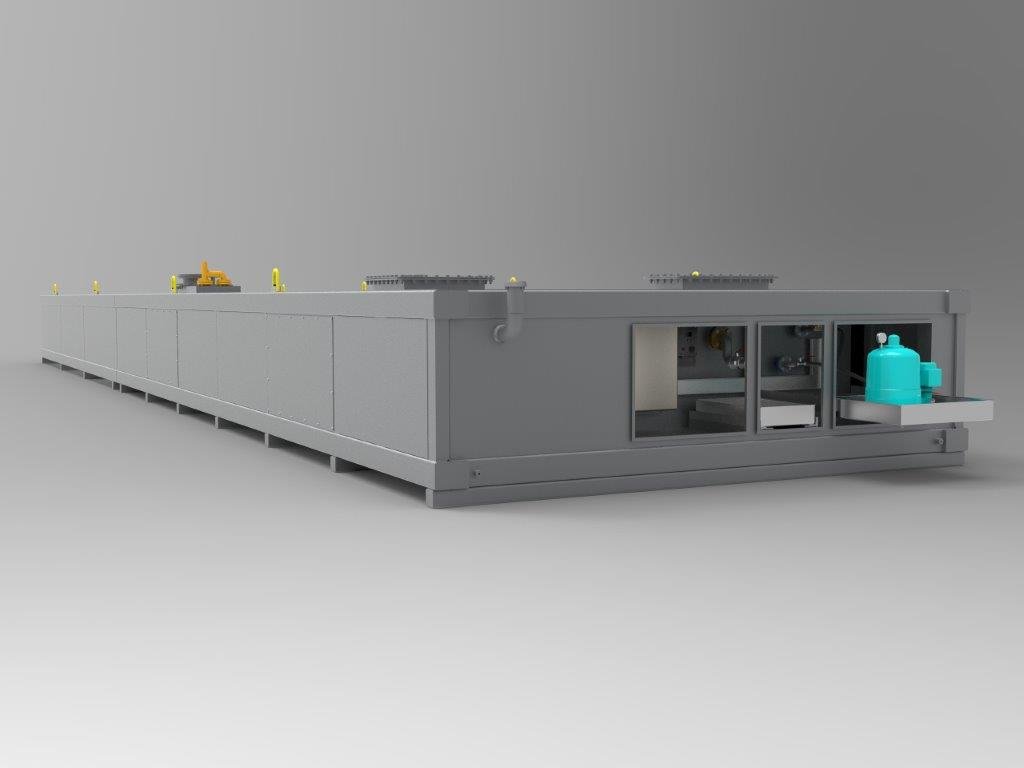

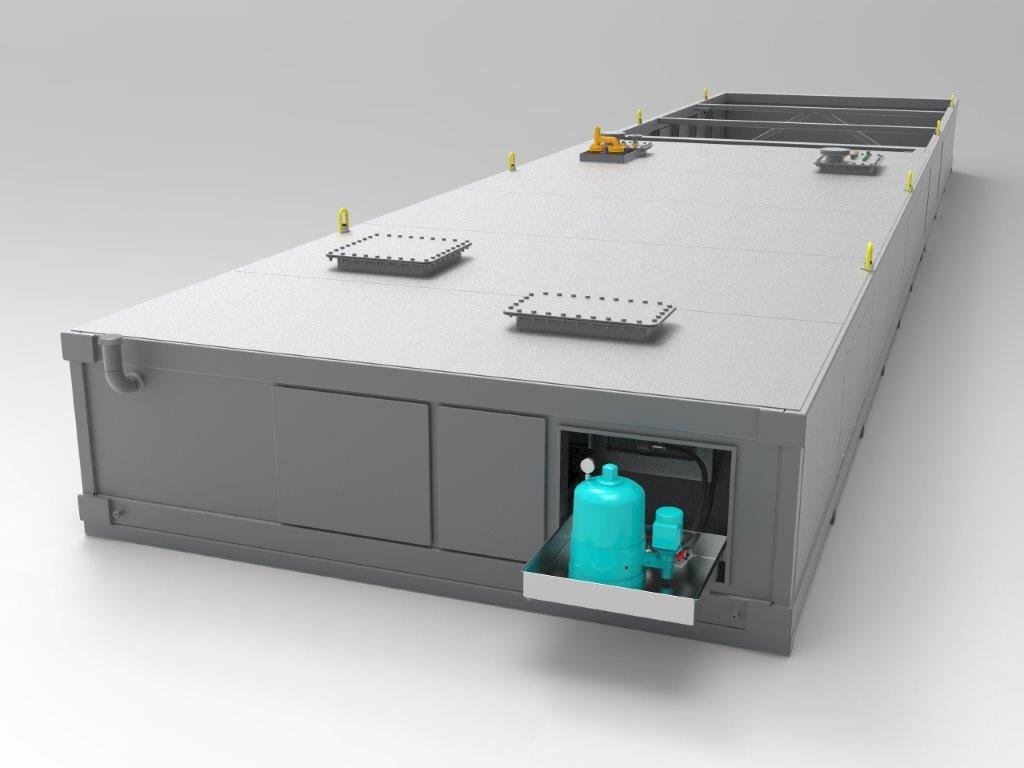

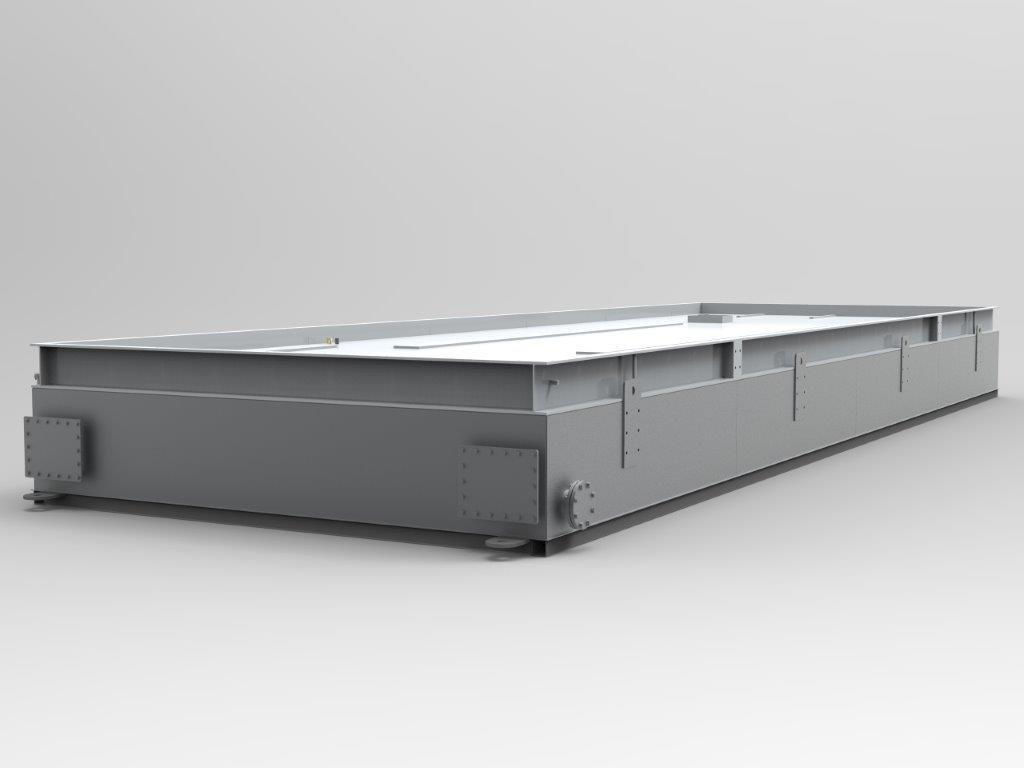

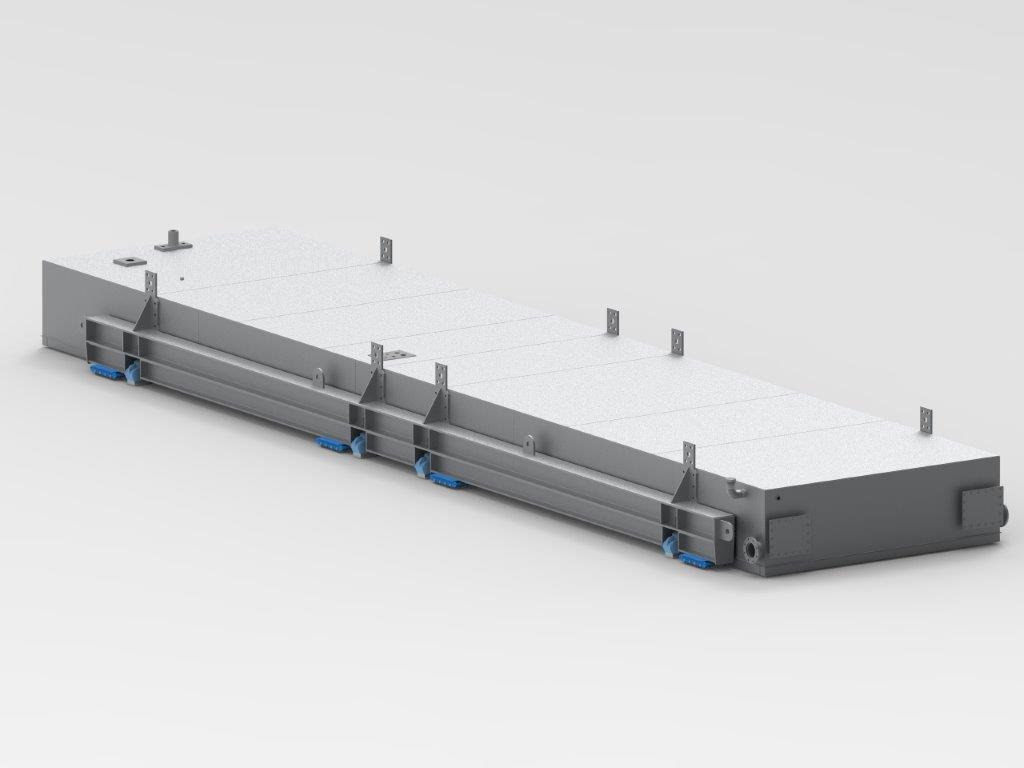

Slab Tanks (Generator Base Tanks)

OTS specialise in the design and build of bunded slab tanks for acoustic/generator container packages. Our slab tanks are specifically engineered to meet the demanding requirements of data centres as well as various industrial applications. They are robust, innovative, and adaptable, making them ideal for scenarios where space optimisation and structural integrity are paramount.

Slab tanks for generator container packages

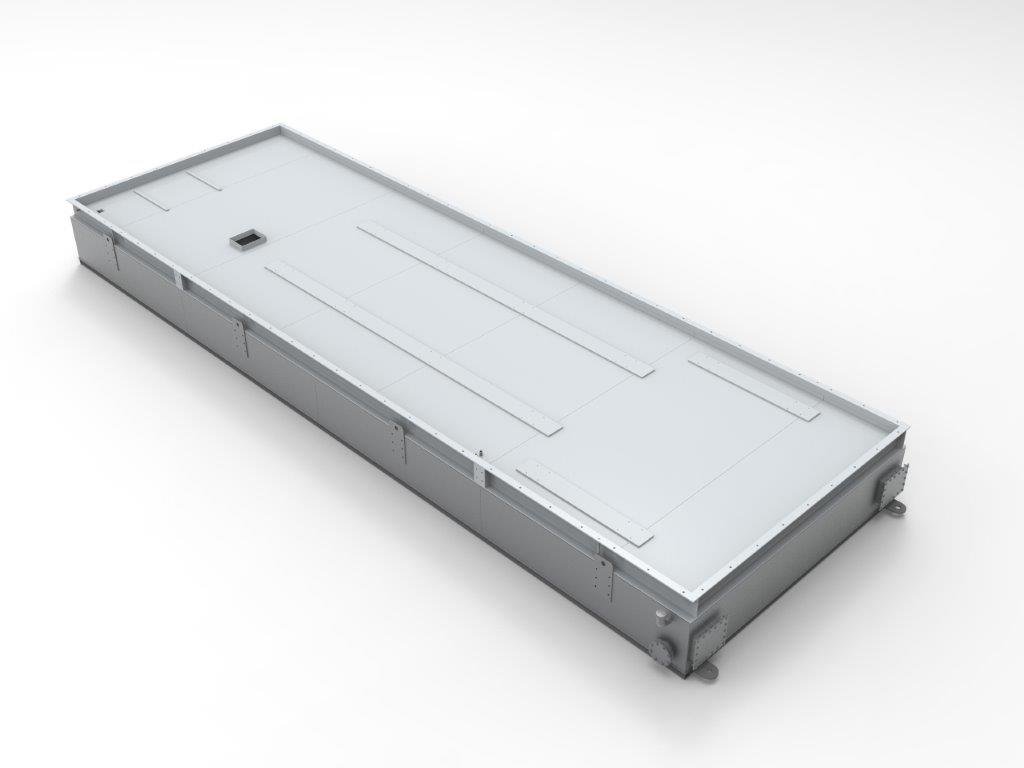

OTS excels in crafting slab or belly tanks designed for space-efficient solutions, particularly in settings where space is a premium. These tanks, typically situated directly beneath equipment, are an ideal choice for data centres and other compact environments.

Key features of our slab tanks include:

-

Our slab tanks are built to align perfectly with the generator's footprint, maximising space utility and ensuring a seamless integration with the existing infrastructure.

-

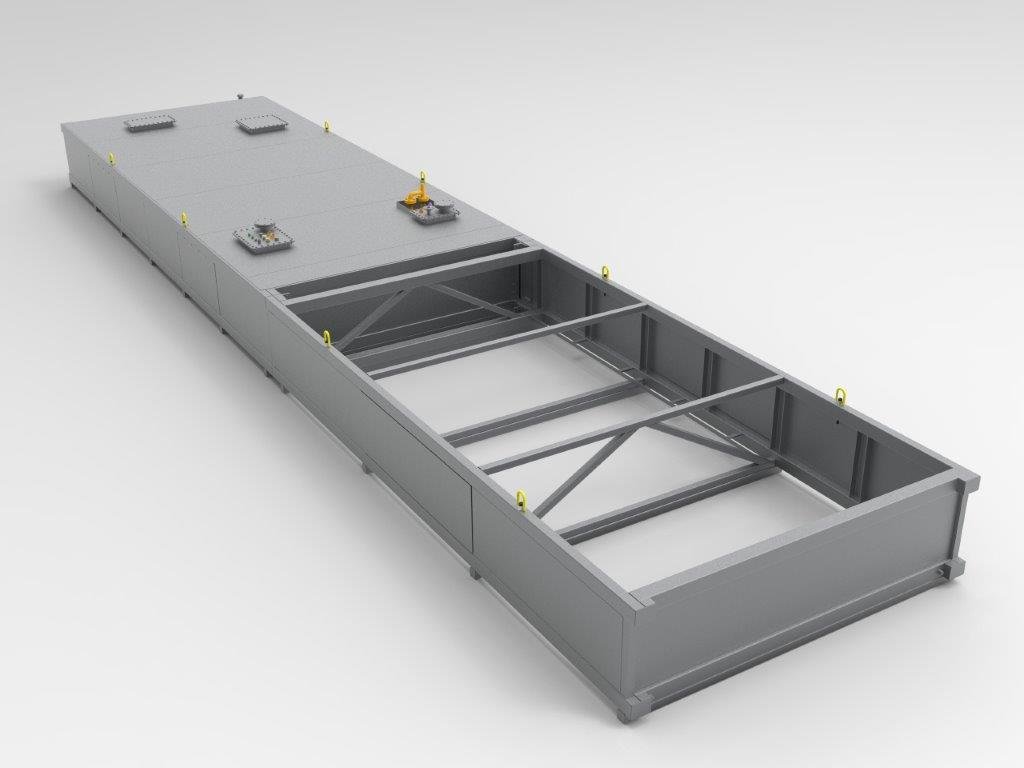

Each tank comprises a robust inner storage unit enclosed within an outer weatherproof bund. This design is crucial for containing any potential spillages or overflows, thereby safeguarding the environment and maintaining operational safety.

-

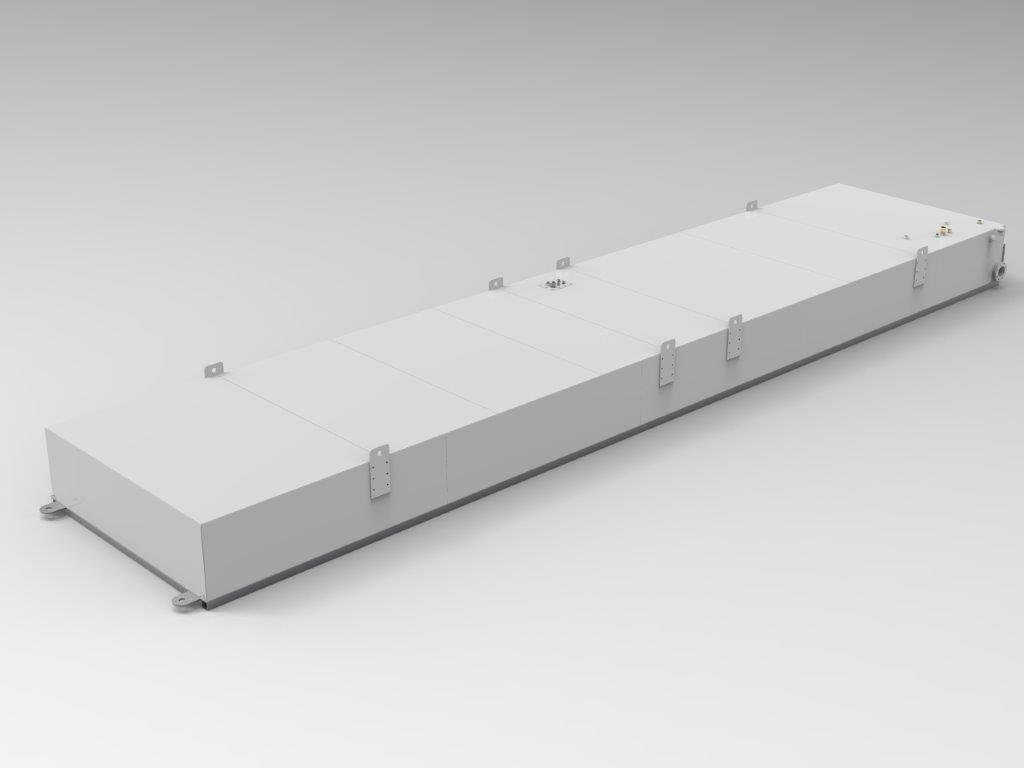

At OTS, we understand that every site has its unique requirements. Therefore, our tanks are custom-designed to meet specific client needs, considering both the site's spatial constraints and the final placement of the tank package.

Slab Tank Capacities & Varieties

OTS excels in the design and build of a diverse range of innovative structural slab tanks designed to meet specific operational needs and spatial constraints.

-

Our tanks come in various capacities, ranging from 10,000L to 40,000L, ensuring a wide range of options to suit different volume requirements.

-

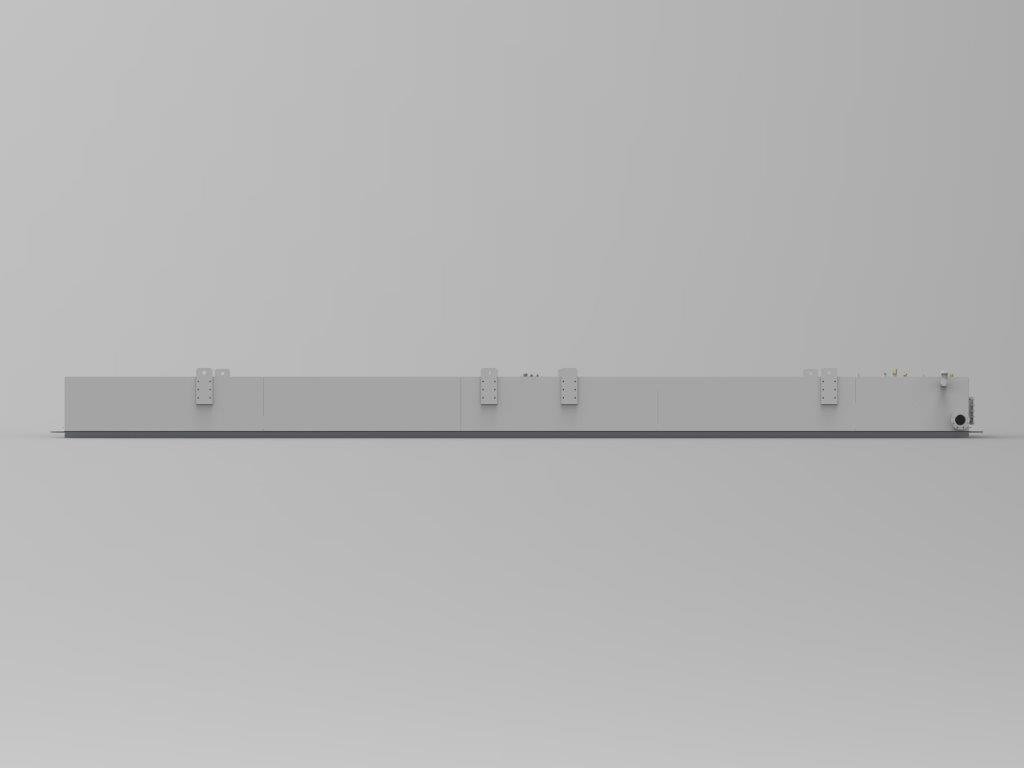

In terms of structural load, OTS slab tanks are designed to support structural loads of up to 75 tonnes in order to support your equipment.

-

Structural slab tanks that are statically loaded with containerised generator sets

-

These are tanks that require “skating” into position with skates positioned below the tank or outboard if height restrictions prevail.

-

These tanks are designed for enhanced structural integrity, particularly beneficial in demanding operational conditions.

Specialised Slab Tank Installation Techniques

OTS employs state-of-the-art installation methods, ensuring seamless and secure placement of slab tanks, even in the most challenging environments. Our expertise in skating and winching provides unparalleled precision in tank installation, adapting to various site requirements.

-

Our advanced skating technique allows for smooth transportation and positioning of tanks, especially useful for 1st floor installations or when access is restricted. For installations with limited headroom, our side beam skates and winching capabilities are instrumental, ensuring tanks are securely and efficiently moved into place.

-

In scenarios demanding intricate manoeuvring, OTS excels in safely and accurately navigating tanks into position. We use awkward lift-and-shift specialists enabling us to manoeuvre 50-60 tonnes into awkward positions.

Our specialised installation techniques ensure that every OTS slab tank is installed with the utmost precision and care.

Customised Design and Engineering

OTS is dedicated to delivering customised slab tank solutions, meticulously engineered to meet each client's unique specifications and site constraints. Our approach is client-centric, focusing on tailor-made designs that align with specific operational and spatial requirements.

-

We prioritise understanding our clients' needs, ensuring every tank is designed to align with their specific criteria, whether it's for capacity, spatial limitations, or operational functionality.

-

Our design team excels in engineering solutions that fit seamlessly within the unique environmental and spatial challenges of each site.

-

OTS has a proven track record of meeting an array of design requirements. From static to dynamically loaded tanks, and those requiring specialised support structures, our engineering expertise ensures each project is executed with precision.

Our customised design and engineering service is our commitment to delivering excellence in every slab tank we create.

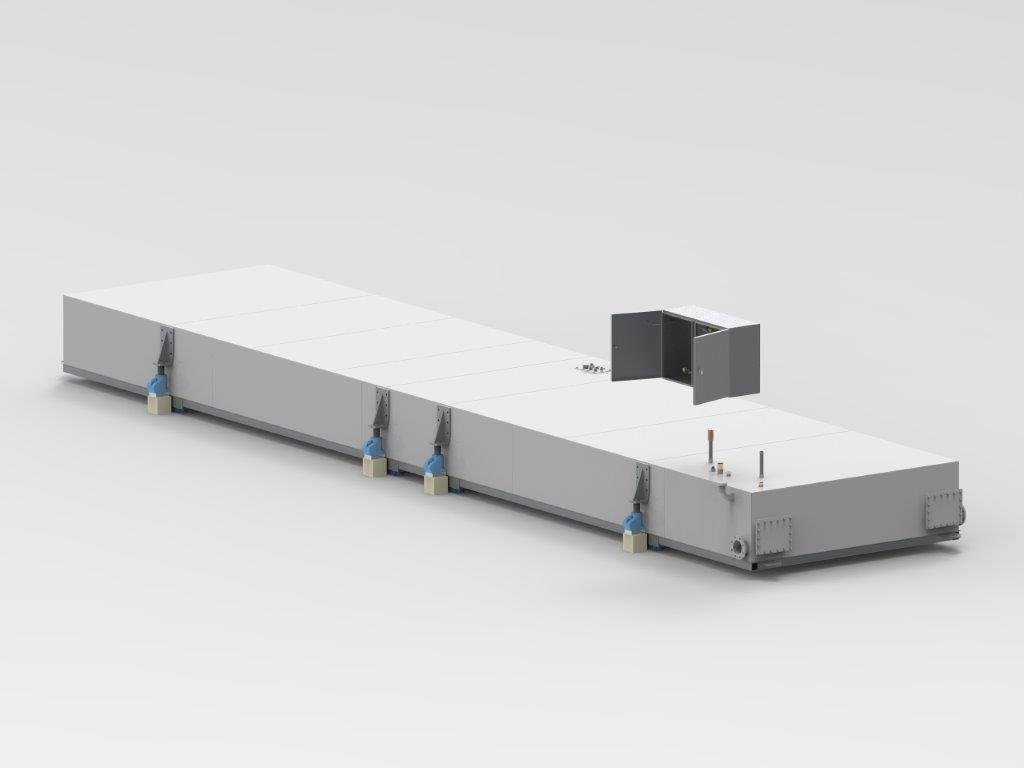

Advanced Features and Equipment

OTS slab tanks come pre-fitted with a suite of advanced features and equipment, ensuring optimal performance, safety, and compliance with industry standards:

-

Automatic Tank Gauging: Precise measurement and monitoring of tank contents for accurate inventory management.

Combination High/Bund Overfill Alarms: Essential safety features to prevent overfilling and potential spillage.

Overfill Prevention Devices (OPD): Critical in maintaining safe fuel levels and preventing environmental hazards.

Fuel Filtration Systems: Including DieselPure, Parker Racor, and CJ Jensen systems for ensuring fuel purity and protecting equipment from contaminants.

Duty/Standby Pump Sets: Guaranteeing uninterrupted fuel supply and operational reliability.

Advanced Pump/Filtration Control Panels: Facilitating easy and efficient management of fuel dispensing and filtration processes.

PLC/HMI: Programmable Logic Controllers and Human-Machine Interfaces for sophisticated control and user-friendly interaction.

Tank Integrated Cabinets: Housing and protecting essential equipment within easy reach.

Remote Fill Cabinets: Enabling convenient and safe external fuel filling.

Remote Filtration Cabinets: Streamlining the filtration process and enhancing maintenance efficiency.

Commitment to Quality and Standards

We take commitment to quality and adherence to rigorous industry standards seriously. We utilise only the most robust materials, ensuring each tank is built to withstand the demands of its operational environment.

-

Every slab tank is constructed from high-grade materials, selected for their durability and longevity. This ensures that our tanks not only meet but exceed industry expectations in terms of quality and resilience.

-

Our manufacturing processes and final products strictly comply with established industry standards. This commitment extends to all aspects of design, fabrication, and installation, guaranteeing compliance with regulatory requirements (OFTEC OFS T200).

-

Safety is at the core of our design philosophy. Our tanks are engineered to provide maximum protection against leaks and spills, safeguarding both the immediate environment and wider ecosystem. By prioritising environmental protection in our designs, we contribute to our clients' sustainability goals and help safeguard the planet for future generations.

OTS's dedication to quality and standards is evident in every slab tank we produce, ensuring reliable, safe, and environmentally responsible fuel storage solutions.

Find out how we can help

For more information or to discuss your project requirements, please contact us below or call us directly on 01386 853409. We're here to assist with any questions or concerns you may have.