Automated Fuel Management Systems Remove the Potential for Human Error

As one of the UK’s leading utilities companies with multiple depot locations across the UK as well as dozens of construction sites with plant, O’Connor Utilities is a significant player when it comes to fuel consumption. With an annual fuel spend of approx. £3 million each year, the recent changes to the taxation of Gasoil as well as fuel price volatility have meant that focus on fuel management has become imperative.

-

This initial project demonstrates the range of OTS Group’s Fuel Storage & Management Systems, helping O’Connor Utilities to achieve peak efficiency, and restrict the potential of mis-fuelling to other vehicles or site plant.

The new refuelling facility has been designed with an enhanced automated fuel management system at its heart which removes the need for manual data entry, and thus potential for human error, and allows O’Connor Utilities to track all vehicle or plant refuelling, whether at home or away, combining depot tank measurements with fuel card usage.

-

The storage tank itself is an OFS T200 Tank Package featuring 55,000L capacity over two compartments for Diesel/HVO and UREA. Manufactured at the OTS factory, the tank features SecuriTank™ integrated steel security cabinets housing fuel dispensing pumps, and tank monitoring equipment.

We have chosen Fuel Dispensing and Tank Gauge systems based on renowned Gilbarco Veeder-Root products, the TLS4B Automatic Tank Gauge and the Twin Diesel/UREA Frontier Fuel Dispensing unit.

-

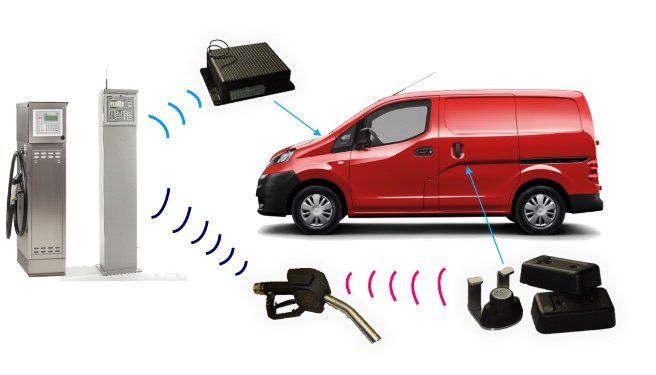

The Fuel Management System deployed on this installation is the Jigsaw M2M Eclipse, installed in combination with Jigsaw’s EasyFuel nozzle-based, automatic vehicle ID System.

The benefits of this system are that it entirely removes the need for human intervention at the pump (in terms of authorisation and entry of odometer). This simple system ensures fuel is only delivered to authorised vehicles, effectively stopping the filling of secondary containers. It also has the added benefit of Automatic Mileage Capture (AMC), ensuring accurate MPG figures & removing the possibility of human error in manual entry of vehicle odometer data.

The EasyFuel nozzle pack is battery powered and completely sealed and hence impervious to rain and dust, making it ideal for mobile refuelling use – a feature that will prove useful if rolled out to all O’Connor sites.

The full Fuel Management System includes access to the fuel web service and will give O’Connor Utilities easy access to their fuelling data. The system is intuitive, with every feature, including in-depth reporting, just where it should be, making the task of fuel management that much easier.

These features will allow O’Connor Utilities to effectively track their fuel usage, preventing misuse and alerting them quickly in the event of rapid level drops associated with fuel theft direct from the tank.

-

O’Connor Utilities have a strong belief that sustainability is critical to their long-term business success and recognise their responsibility to the natural environment and understand the social impact that they have on the areas in which they work. As a result, one of the core principles in the design was the reduction of fuel consumption and the move to sustainable fuels where possible.

The Fuel Storage System is designed to dispense HVO (a drop-in fuel that can be used directly in the tank) so that O’Connor Utilities is able to make the switch as soon as is viable.

The Fuel Management System will have the added sustainability benefit of enabling O’Connor Utilities to closely monitor & optimise vehicle and plant performance (based on MPG statistics) by staying on top of repairs and driver behaviour.

O’Connor Utilities briefed us to design, build & install an updated refuelling facility that would benefit from an automated fuel management system in order to restrict the potential of mis-fuelling, remove the ‘human error’ variable and enable them to track fuel consumption across fleet & plant with a view to rolling the system out across their sites in Manchester, North & South Wales and Yorkshire.

We are delighted to be working with O’Connor Utilities and look forward to the development of their UK-wide refuelling facilities.